MACHINERY

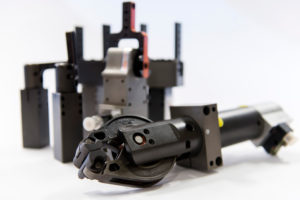

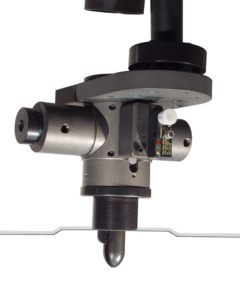

BalTec

Wherever high-quality riveting applications are required, BalTec’s riveting technology offers most sophisticated and advanced solutions. Even in the case of joints where formerly only non-rivet technologies were an option.

WHO WE ARE

With its headquarters in Pfäffikon, Switzerland, the BalTec Group sees its core competence in the manufacturing of joining technology machinery, with a special focus on radial riveting technology, but also orbital riveting, roller forming and pressing.

As early as 1968, BalTec (then still known as Bräcker) had already made radial riveting technology a familiar process in a variety of different sectors.

Today we are the global leader in riveting technology, encompassing six companies with over 60 direct employees and 40 sales partners on every continent.

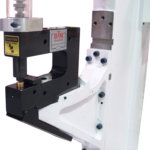

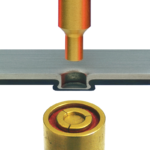

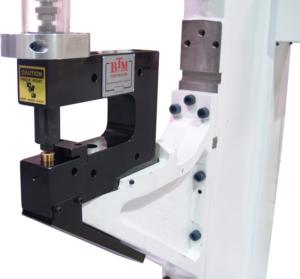

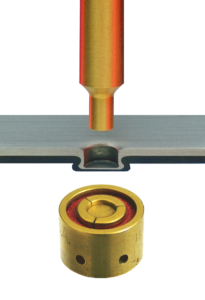

BTM

BTM is a global leader in the design and engineering of specialty presses, production systems, precision tooling and work holding equipment. For over 50 years, BTM has provided customers with innovative equipment and tooling in the sheet metal industry.

BTM originated the sealed clinch joint and is the global leader in developing clinch joining technology along with premium tooling and manual and automated clinching equipment and presses. BTM patented Tog-L-Loc® sheet metal joining system is used in the automotive, appliance, HVAC, construction, electronics furniture and other industries the world over.

100,000 styles, sizes and combinations of BTM tooling, designed and engineered with premium tool steels and precision manufacturing to produce high integrity joints, long tool life and accommodate material and processing variations. BTM application engineers work with you to select the optimal tooling and equipment.

FAR

FAR has been producing high technology fasteners (blind rivets, blind rivet nuts and tools) with guaranteed maximum efficiency and performance in service and quality of product.

Through an established domestic and international sales network, Far sets the standard for companies needing consistent reliability.

Far’s policy is the constant improvement achieved by investment and professional on-going training of its staff.

This is how Far can offer state-of-the-art, reliable fasteners and full technical and after-sales service.

FAR – Is not just a supplier, but a partner with its customers. Our aim is customer satisfaction!

HBS

HBS International success with innovative products and solutions

In more than 40 years of its existence, our medium-sized company from Dachau/Bavaria has attained an export share of over 50% by establishing itself in more than 50 countries across all continents. HBS supplies a complete product range:

Nut and stud welding technology for manual, semi-automatic and fully automatic applications along with welding elements and accessories.

Worldwide valid patents, numerous national and international awards for innovations and technology transfer confirm us to be a worldwide leading company in this industry.

With HBS you have access to a comprehensive product portfolio. We offer: 2 welding processes – 12 model series and over 50 model variants. As different as the applications may be – we have the right solution, the right welding process and the right welding equipment for every one of your requirements.

Download our brochure here:

HBS Welding Elements

LAG

Resource Sheetmetal Machinery is a specialized exporter of machine tools, mainly focus on CNC press brake, Cutting machine, Fastener insertion machine, Punching machine, Notcher machine, Production line as well as other different kinds of machine tooling and accessories.

Our customers are widespread in more than 10 countries including Germany, Spain, France, England, Greece, Finland, Norway, Canada, South America, Middle east, Australia, Austria, Africa and Southeast Asia etc.

Our principle is offering high quality machines and good service to all the customers . We will give you quick response upon any of your need.

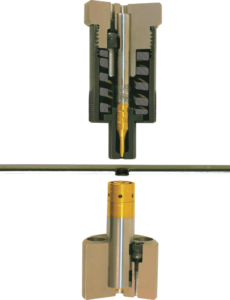

Rolleri Up-Grind

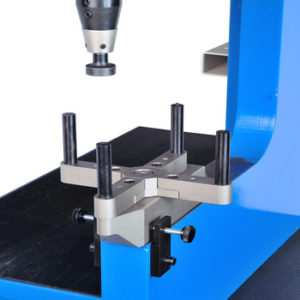

Sharpening can give a tool exactly the same properties as a new one, but it requires a high-quality sharpening device. The tools are often made of special steel, in which case the sharpening process must be correct so that the tool is not damaged.

A properly sharpened tool gives a better cutting mark, reduces noise and strain on the machine, reduces the purchase of new tools and thus saves money.

The Rolleri Up-Grind sharpening device is designed for sharpening the tools of punching machines. It meets high quality standards regarding structure, power and cooling.