ECCENTRIC MACHINERY TOOLING

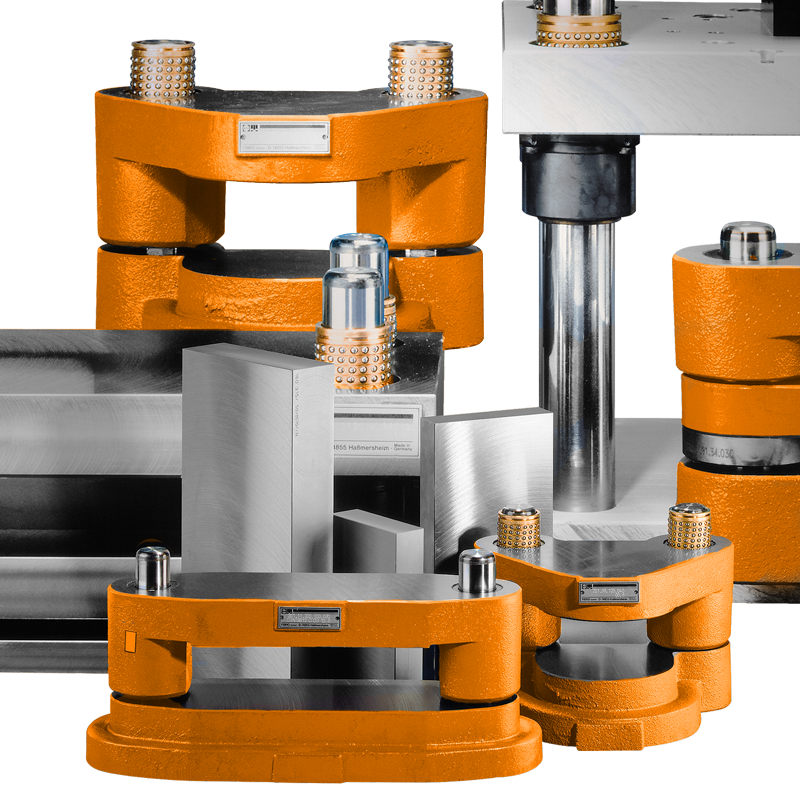

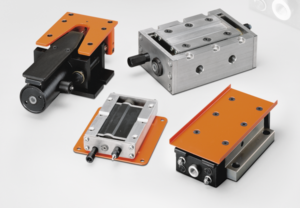

FIBRO

We offer a wide range of elastomer springs, spring shape elements, ejectors and scrapers made of polyurethane rubber. Under the column „elastomers“, you can convince yourself that FIBROFLEX® elastomer springs cannot only be used as pure spring elements but also as forming elements.

During continuous loads, elastomers loose some of their abilitiy to regain the original shape. Over time, deformation residue occures, i. e. the elastomer settles. Depending on the spring displacement utilisation, the tendency towards initial sagging relating to the original spring height amounts to 8 – 10 %.

With ample stock levels and rapid delivery schedules for standard parts manufactured in its factory in Hassmersheim, Germany, FIBRO has become a household name around the world.

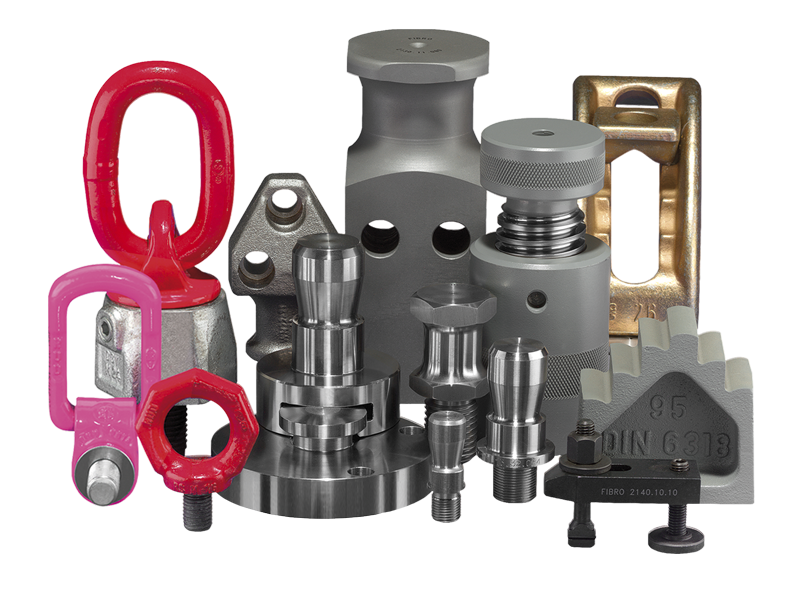

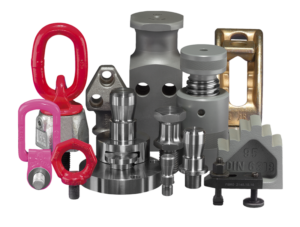

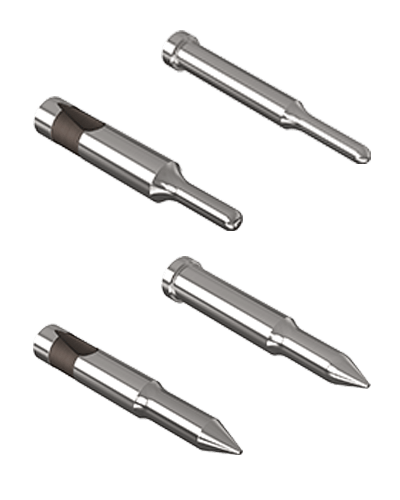

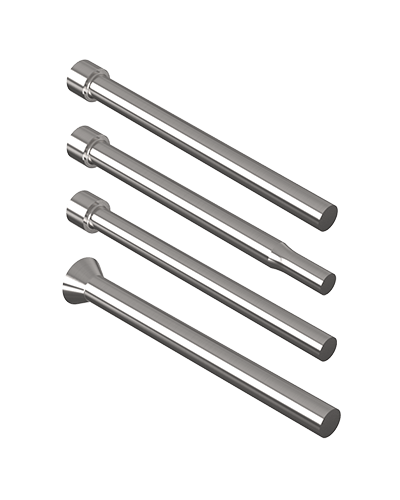

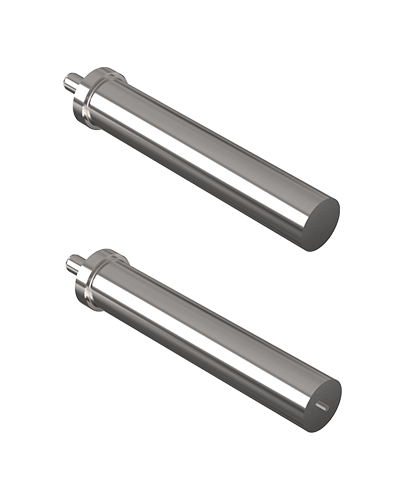

DAYTON

DAYTON LAMINA™ is the world-wide industry leader in the production of catalog and special punches, die components, die details, punch blanks and metalstamping tools. Our full line of tooling includes everything in your bill of materials, punches, die buttons, pins & bushings, wear and guide components, die springs, cams, die details, punch retainers and more.

Only DAYTON LAMINA™ can offer you…

- Shortest, most consistent delivery. Our punch & die Firm Delivery Schedule reduces your leadtime, maintenance downtime and inventory. Our in stock catalog die components are available for immediate delivery.

- Most comprehensive range of product, industry leading brands. More variety than any other metal stamping tooling manufacturer, meeting all your metal forming tooling requirements.

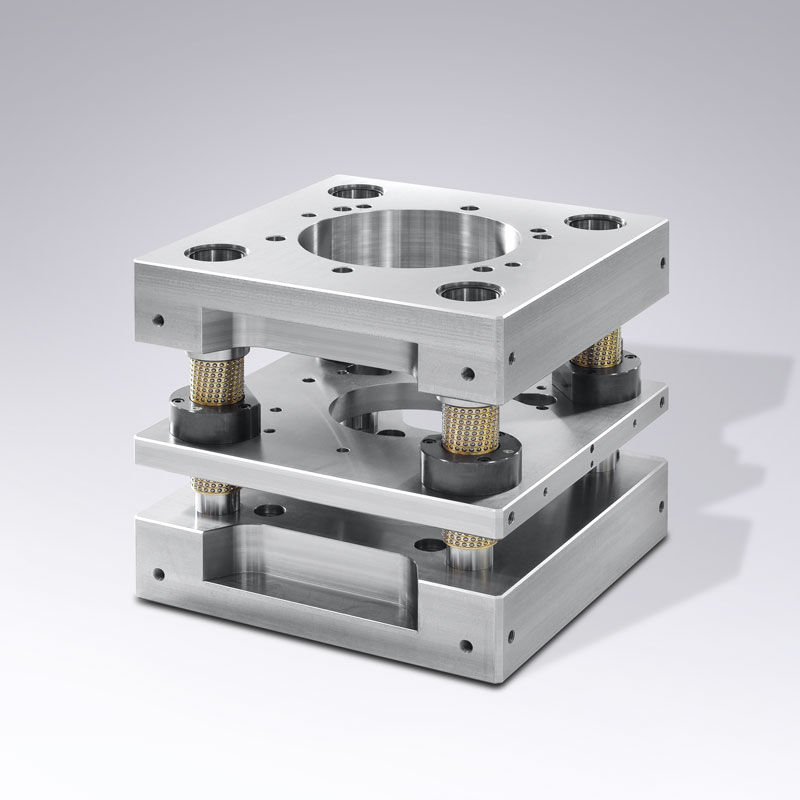

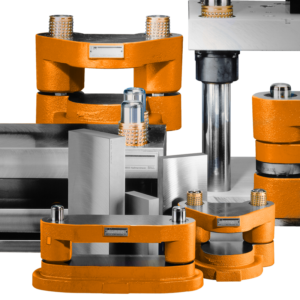

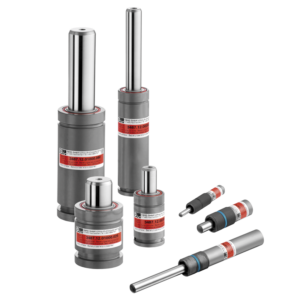

KALLER

KALLER is the world-leading brand for gas springs and gas hydraulic systems for stamping dies and counterbalance, as well as gas hydraulic suspension systems for heavy duty off-road vehicles.

The company behind KALLER is Strömsholmen, in the small community Tranås in Sweden. The company is a business of Barnes Group Inc. (NYSE:B), located in the U.S.

Since 1983 we have developed and refined the gas spring technology, but we have been in the business since 1876 – for many years as a world-leader, with an export share of 95 percent.

KALLER gas springs uses compressed nitrogen gas, contained in a cylinder and compressed by a piston rod, to exert a force.

The benefits of gas springs, compared to typical mechanical springs, are:

- ability to create higher force in less space

- immediate presence of force when stroked

- low force increase over the stroke

- easy to adjust the force by increasing or decreasing the amount of gas in the spring.

With the KALLER Force and Temperature Calculator you will be able to determine force profile and operating temperature of the gas springs, even before finishing the tool design.

KALLER gas springs are designed to meet customer expectations for reliability, safety and service life mainly in sheet metal forming applications. But they are capable to handle numerous other applications where high force or energy storage efficiency is required.

The design, manufacturing and testing of KALLER gas springs has been approved according to the European Pressure Equipment Directive (2014/68/EU).

Only DAYTON LAMINA™ can offer you…

- Shortest, most consistent delivery. Our punch & die Firm Delivery Schedule reduces your leadtime, maintenance downtime and inventory. Our in stock catalog die components are available for immediate delivery.

- Most comprehensive range of product, industry leading brands. More variety than any other metal stamping tooling manufacturer, meeting all your metal forming tooling requirements.